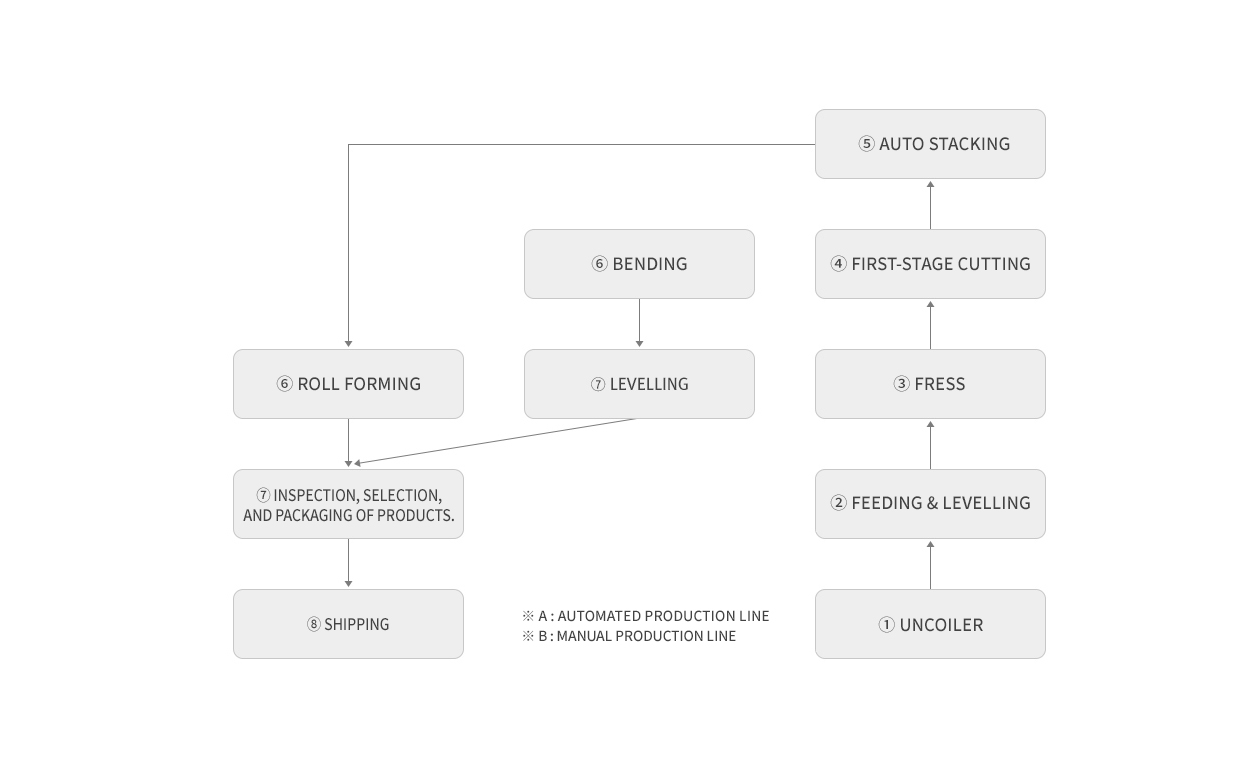

Manufacturing Process

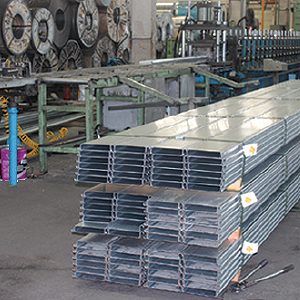

Parking deck production process

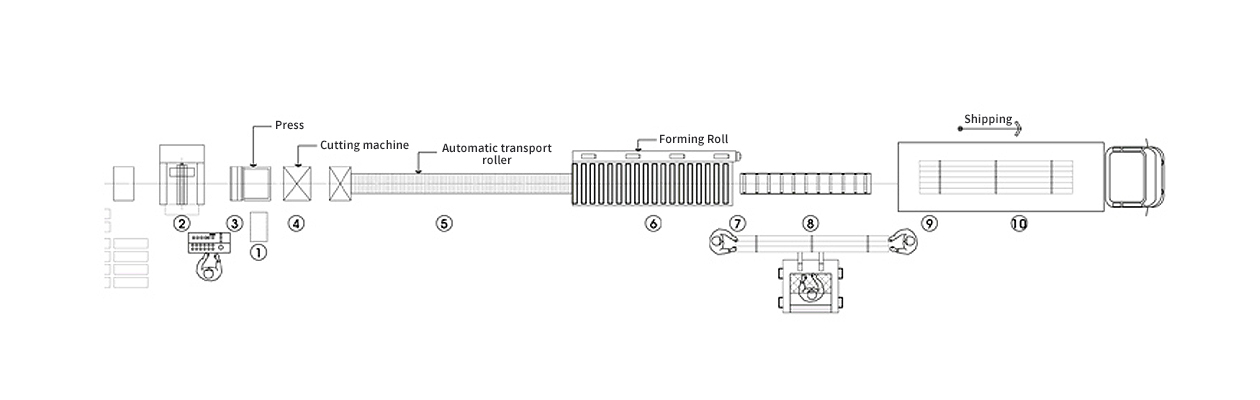

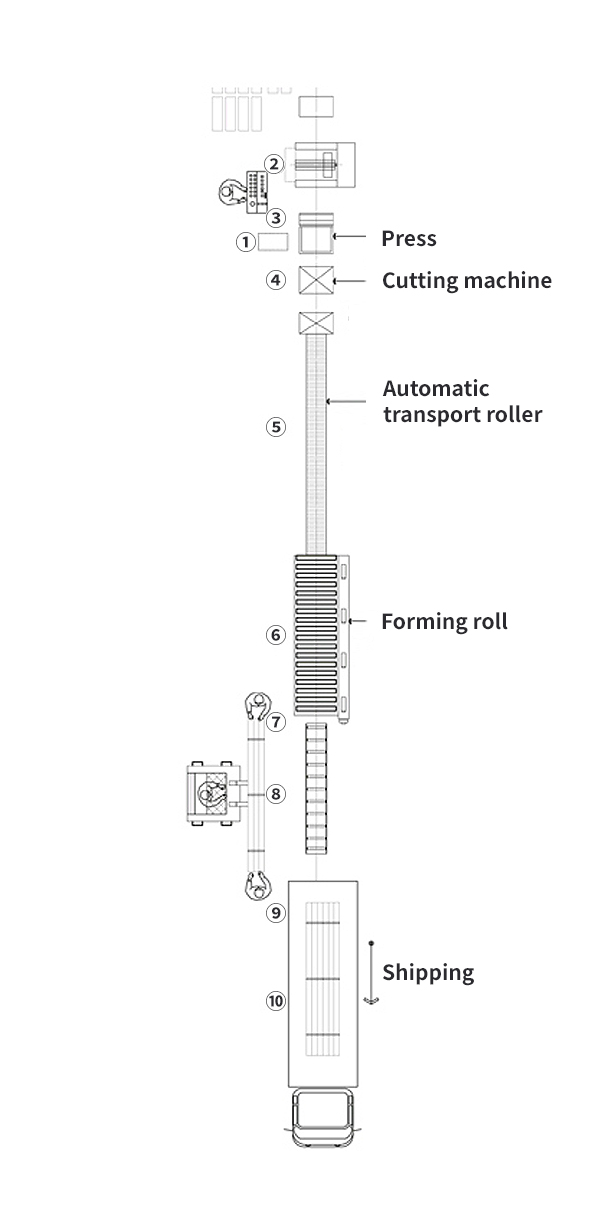

1. Mold pin replacement → 2. Raw material coil insertion → 3. Mold processing and shaping → 4. Product dimension cutting →

1. Mold pin replacement → 2. Raw material coil insertion → 3. Mold processing and shaping → 4. Product dimension cutting → 5. Transport via material foaming → 6. Material foaming processing for product shape → 7. Product inspection →

8. Product selection and packaging → 9. Checking product loading quantity → 10. Product shipping and delivery

1. Raw material input

1. Raw material input

2. Mold processing

2. Mold processing

3. Foaming

3. Foaming

4. Product packaging

4. Product packaging

NON SLIP PLATE